Achieving Efficiency and Growth: The Benefits of Lean Product Development

22 February 2024

22 February 2024? Listen to the Summary of this article in Audio

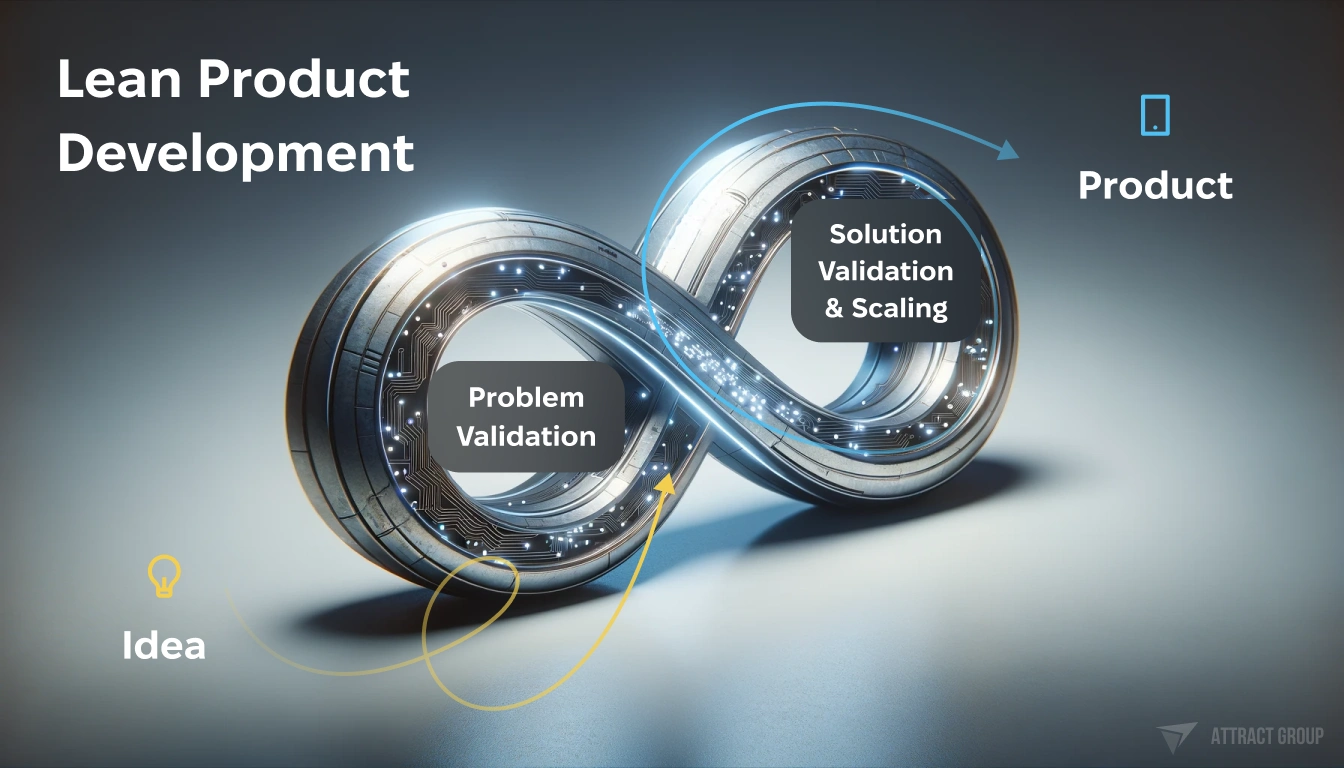

As companies face the monumental challenge of innovating while minimizing risk, the principles of lean product development have never been more valuable. With a staggering 70% of projects stumbling in the product development stage, it is imperative for businesses to adopt a customer-centric development approach that not only drives efficiency growth but also ensures the delivery of value-adding solutions. The robust framework of lean product development is built on a foundation of relentless continuous improvement, facilitating a process geared towards understanding customer needs, expediting market delivery, and maximizing resource utilization.

In the heart of LEAN practices lies the commitment to refining the product development process through iterative design, cross-functional collaboration, and a fascination with excellence. Lean principles demand that waste be excised with surgical precision, fostering an environment where innovation thrives and products transform to meet the evolving desires of the market effectively. The primary aim of this methodology is not just the conservation of time and resources, but also the cultivation of enduring customer relationships grounded in satisfaction and trust. In this way, lean product development steers organizations toward a brighter horizon of sustainable growth and competitive agility.

Introduction to Lean Product Development

In an era marked by rapid technological advances and consumer demand for innovative products, the adoption of lean principles has become imperative for sustaining competitive advantage. Originating from the innovative measures of the Toyota Motor Company to challenge its resource-rich counterparts, lean manufacturing revolutionized traditional production techniques. Taking cues from its manufacturing predecessor, the agile product development approach moulds the same philosophy to suit the dynamic realm of software creation and general product innovation.

The Origins of Lean: From Manufacturing to Software Development

The inception of lean manufacturing is a tale of triumph over adversity, with its roots deeply embedded in the post-war industrial landscape of Japan. As Toyota fought to compete against the American automotive giants, it evolved an efficient system focused on minimizing waste and being more agile—all foundational concepts of the lean startup methodology we see today. This approach allowed for a flexible and adaptive operation, which was crucial in an era of limited resources and high market uncertainty. These same lean principles have now transcended the manufacturing floor, finding relevance in today’s lean software development and modern agile frameworks, empowering businesses to create more nimble and waste-averse product cycles.

Principles of Lean Product Development

The transition from manufacturing to product development necessitated a contextual reshaping of the lean philosophy, culminating in core principles that guide today’s agile product development strategies. At its heart lies the prioritization of customer value — a principle that follows through from the meticulous identification of value to the streamlined delivery of product features that consumers truly seek. The lean methodology emphasizes the iterative cycle of learning and improving, ensuring that products not only meet current customer demands but are also primed to evolve with changing market trends. Through fostering cross-functional collaboration, lean product development champions a holistic approach that fuses diverse expertise and promotes transparency across all project phases. Indeed, the agile spirit of lean continuously drives product innovation and organizational growth.

Core Benefits of Lean Product Development

The strategic enactment of lean product design shines most brightly through its array of benefits, enhancing not just the final products but the very foundations of the development process. As enterprises grapple with the demands of a shifting landscape, these core benefits underscore why lean project management and value stream mapping in product development are more than just methodologies — they are necessary pillars for continuous improvement and sustained growth. Let’s delve into the transformative power of Lean Product Development (LPD).

Minimizing Waste to Maximize Value

At the forefront of lean product development is the goal to eradicate inefficiencies; this is achieved through painstaking value stream mapping in product development. By distinguishing and eliminating non-value-adding activities, companies are able to focus their resources on efforts that directly contribute to the end goal — delivering value to the customer. This filtration process not only slashes unnecessary costs but also serves as a fulcrum for value maximization.

Enhanced Flexibility and Responsiveness

The lean approach is inherently adaptable, equipped to navigate and capitalize on the fluidity of market trends and consumer expectations. Continuous improvement in product development is a key characteristic, enabling organizations to rapidly iterate and respond to feedback. This agility is a hallmark of competitive success, as it allows for quick pivots and dynamic solutions in response to new information and emerging opportunities.

Faster Time to Market

Brevity in development timelines is a pivotal benefit of lean product development. By streamlining processes and removing redundant steps, products traverse from concept to market-readiness at an expedited pace. This swift turnaround not only satisfies the increasing consumer expectation for rapid innovation but also allows businesses to stay ahead in the relentless race to market leadership.

Increased Team Productivity and Morale

Lean product development fosters a productive environment where team members can thrive. With reduced bottlenecks and clearer objectives, teams work more cohesively, bolstering morale and productivity. Lean project management practices contribute to a culture of empowerment and ownership, where contributions are valued and recognized.

Continuous Learning and Improvement

Continuous improvement in product development is not a one-time event but a perpetual cycle in the lean philosophy. There’s an ingrained tradition of reflection and enhancement, with iterative cycles furnished with lessons learned, which are swiftly integrated into subsequent phases of development — be it product planning, design, testing, or launch.

Better Customer Satisfaction

Lean product design begins and ends with the customer. By intimately mapping the customer’s journey and iteratively refining the product, companies are able to deliver solutions that align closely with user needs and desires. This not only nurtures customer satisfaction but catalyzes the formation of lasting relationships based on trust and value.

Cost Reduction and Improved ROI

The judicious management of the lean product development cycle can substantially lower overhead costs, making funds available for other critical investments. This economical efficiency, combined with the delivery of high-quality and valuable product offerings, often yields an impressive return on investment, situating LPD as an attractive strategy for judicious financial stewards.

With the integration of lean principles, organizations herald a new era of product development — one infused with precision, customer-orientation, and continual growth. Lean product development is not just a process but a transformative journey towards operational excellence and market differentiation. It is these core benefits that collectively position lean methodologies as indispensable in the modern development arsenal.

Our expert software developers can build custom solutions to help streamline your product development processes.

Lean Product Development in Start-ups

Embracing the lean startup model, characterized by ingenuity and agility, is becoming increasingly essential for start-ups seeking sustainable growth. The fusion of lean principles in product development with the adaptability of agile product development creates a potent methodology for these young businesses to enhance their market position and nurture continuous innovation.

Navigating Initial Growth with Lean Principles

Start-ups are in a unique position to incorporate lean principles from inception. The imperative to “lean-in” is not just about reducing costs; it’s about adopting a philosophy of continual learning and a commitment to developing products that truly resonate with customers. The opportunity to refine products through a process of validation and iteration aligns perfectly with the nimble nature of start-ups, allowing for a strategic approach to achieving product-market fit.

Case Studies: Successful Lean Start-ups

Stellar examples of start-ups implementing lean principles abound, yet few resonate as strongly as Spotify and Toyota. Spotify employed an agile, customer-feedback loop to release music streaming features that resonated with its audience, growing from a modest start-up to a dominant industry player. Forming a stark contrast but adhering to similar lean tenets, Toyota integrated input from cross-functional teams to address post-production issues and enhance their vehicles continuously.

Overcoming Common Start-up Challenges with Lean

Start-up challenges, such as limited resources and the pressure to quickly deliver products to market, are mitigated with the lean approach. By focusing on building a minimum viable product and leveraging real-time feedback for improvements, start-ups are equipped to respond to customer needs without overextending resources. This customer-centric focus is at the heart of innovation, fostering products that not only meet but exceed market expectations with agility and efficiency.

“Incorporating lean principles early on is the linchpin of sustainable start-up growth. It’s a philosophy that serves as both a compass and catalyst for innovation and market viability.”

Lean Product Development in Established Companies

For established companies, integrating lean product development represents not just a strategy shift but a cultural overhaul. The alignment of lean manufacturing techniques with decade-spanning company structures heralds a new age of efficiency, innovation, and continuous improvement. Such integration often leads to a sweeping revitalization of products and practices, breathing new life into traditional business models and enabling them to stay nimble in a dynamic market.

Integrating Lean into Existing Company Structures

Melding lean methodology seamlessly into the existing infrastructure of prominent businesses involves a pragmatic blend of executive buy-in, team re-education, and process re-engineering. It demands that all layers of the organization, from senior management to junior staff, adopt a mindset bent on minimizing waste and optimizing workflows for maximal productivity and value creation.

Revitalizing Product Development in Large Enterprises

Embracing lean principles provides established companies with the tools to dissect and reconstruct their product development processes. Through a fundamental commitment to eliminating inefficiencies, these corporations can revamp their systems to support rapid innovation cycles, promptly adapt to technological shifts, and create more customer-centric products.

Case Studies: Lean Transformation in Established Companies

Apple Inc. serves as a benchmark case study for lean transformation within well-established enterprises. The iconic tech leader’s commitment to lean principles is evident in its meticulous design process, characterized by a waste-averse approach and a deep understanding of consumer desires. This dedication ensures that Apple continues to churn out revolutionary products that shape industry standards and consumer habits.

Large-scale entities are increasingly turning to the fundamentals of lean manufacturing techniques to reinvent themselves, cutting through market noise and highlighting their brand as a beacon of innovation and customer satisfaction.

Let our team of specialists help you integrate lean product development into your existing business systems.

Implementing Lean Product Development

Embarking on the lean product development journey requires a strategic approach that transforms the foundational aspects of conventional product development processes. It necessitates a precise alignment of methods and mindsets towards lean principles, ensuring the implementation paves the way for increased efficiency and a culture of continuous improvement. To successfully adopt lean product development, organizations must integrate a broad spectrum of sound practices, cutting-edge tools, and a reliable system to measure impact.

Getting Started: Steps to Implement Lean

The transition to a lean product development process involves a series of deliberate steps that refine the approach a business takes towards creating new products. Central to this approach is a shift in focus towards maximizing value and eliminating waste — a culmination of precise problem identification, careful product planning, disciplined iterative building, and unwavering commitment to process improvement. Successful implementation starts with a comprehensive understanding of these steps:

- Establishing a clear vision aligned with customer value and business objectives.

- Value Stream Mapping to identify and eradicate non-value-added processes.

- Formulating a lean project management framework to guide cross-functional teams.

- Applying lean software development methodologies for iterative and incremental building.

- Integrating kaizen for continuous, incremental improvements.

Tools and Technologies to Support Lean Development

An arsenal of tools and technologies is vital in supporting the lean development process and achieving the refinement of product offerings. These tools leverage data analytics and agile frameworks, such as Usermaven, that are imperative for capturing and understanding customer behavior, thereby enhancing the overall value of products delivered to the market.

| Tool/Technology | Purpose | Benefits |

|---|---|---|

| Usermaven Analytics | Real-time monitoring and analysis of user behaviour | Insights for customer-centric development |

| Agile Frameworks | Facilitate iterative development | Flexibility and rapid response to change |

| Kanban Boards | Visual project management | Clarity on workflow and task progression |

| Kaizen Meetings | Regular team discussions to identify improvement areas | Culture of continuous improvement |

We can build customized software tools tailored to your specific needs to enable lean product development.

Measuring the Impact of Lean Implementation

Monitoring the effectiveness of lean practices is essential for understanding the benefits and areas for further development. Metrics play a crucial role in tracking progress and evaluating the impact of lean initiatives. They provide objective data that can help refine the product development process further.

| Impact Area | Metrics | Desired Outcome |

|---|---|---|

| Efficiency | Time-to-market, cycle time | Shorter development cycles |

| Cost Savings | Cost reduction percentage, ROI | Decreased development costs |

| Quality Enhancement | Defect rates, customer satisfaction scores | Improved product quality |

| Productivity | Throughput, labor efficiency | Increased output with fewer resources |

Lean Product Development Challenges and Pitfalls

While lean principles and the agile product development approach within the lean startup methodology continue to revolutionize the product lifecycle, practitioners often encounter specific challenges and pitfalls. Acknowledging and understanding these potential issues ahead of time can empower teams to navigate the lean landscape more effectively, avoiding costly setbacks.

Identifying and Avoiding Common Mistakes

One of the fundamental missteps in the adoption of lean product development is neglecting to truly understand and define customer value. Without a clear and accurate determination of what the customer deems valuable, all lean efforts may end up misguided, yielding products that miss the mark. Moreover, improper value stream mapping can introduce inefficiencies, ironically creating waste rather than diminishing it. Vigilance in these areas ensures that lean principles harmoniously guide the development process toward better outcomes.

Balancing Lean with Other Development Methodologies

Another critical consideration is the blending of lean thinking with other development methodologies, such as the agile framework or Kanban. While these approaches share common ground, balancing their methodologies requires a deep understanding of their unique benefits and how they can complement one another. Teams must avoid becoming too rigid in their lean approach and instead embrace a flexible mindset that fosters cross-functional collaboration, employee empowerment, and continuous learning. By doing so, organizations can leverage the strengths of lean, agile, and other methodologies to drive innovation and efficiency.

Ultimately, the journey of integrating lean product development into an organization is nuanced and complex. It calls for an ongoing commitment to education, alignment, and refinement. As companies traverse this path, they must remain vigilant against complacency and maintain the agility to adapt, ensuring that the principles of lean continue to engender growth and innovation.

The Future of Lean Product Development

The evolution of lean product development continues to surge forward, integrating cutting-edge trends and pioneering innovations that promise a seismic shift in how companies approach product creation. These advancements, deeply rooted in lean methodology and its principles, signal an era where continuous improvement and innovation become the driving forces behind creating superior customer value and achieving scalable efficiency.

Trends and Innovations in Lean Practices

Emerging technological trends are setting the stage for a new chapter in lean practices. Key among these are advancements in data analytics and artificial intelligence (AI), which are providing unprecedented levels of insight and precision in understanding customer behaviors and preferences. The integration of augmented reality (AR) into the product design process is enabling a more interactive and user-centric approach to product development. These innovations facilitate a more profound connection between customers and products, ensuring that product offerings are not only efficient but also resonate deeply with end-users.

Scaling Lean for Large-Scale Operations

As organizations grow, the principle of scalability becomes central to the expansion of lean practices. The challenge lies in scaling up lean methodologies to larger operations while retaining their core of agility and responsiveness. This means adapting lean principles to complex procedures, ensuring that even the most extensive operations can benefit from lean’s focus on minimizing waste and maximizing customer value. The end goal remains unaltered: to perpetuate an organizational ethos of innovation and efficiency that stands resilient in the face of rapid growth and change.

To realize the potential of lean practices on a grand scale, organizations are looking at ways to weave these principles holistically into their operational fabric. This calls for strategic alignment, a firm commitment to customer-centric approaches, and the cultivation of a dynamic, learning-oriented corporate culture. The path forward for lean product development is clear: as companies adapt and thrive, these methodologies are set to play a pivotal role in underpinning the innovative capabilities of industry leaders.

Conclusion

At the core of lean product development is the uncompromising pursuit of delivering customer value, enhancing efficiency growth, and spearheading innovation. This methodology serves as an exemplar of how entrepreneurs can position themselves advantageously in a tumultuous market by adopting practices focused on customer-centric development and waste minimization. In doing so, they can realize shorter development cycles, boost customer loyalty, and foster prudent financial management.

Entrepreneurs seeking to make their mark must recognize that lean product development offers more than process improvements — it embodies a philosophy that underpins a company’s very approach to market presence and product relevance. By imbuing their operations with the ethos of lean, businesses are not just committing to operational advancement but to building a legacy of quality and customer fidelity.

Recap of Lean Benefits and Final Thoughts for Entrepreneurs

In a recapitulation of the benefits of lean product development, we observe a clear alignment with the outcomes sought by driven entrepreneurs: remarkable efficiency growth, cycling of innovative solutions, and products developed with a keen focus on the customer’s needs. It is this interplay of strategic development and customer orientation that allows startups and established enterprises alike to stay agile in a landscape fraught with challenges.

Lean product development champions continuous improvement as a foundation, infused into every project, ensuring products not only serve the demands of today but are also adaptable for the unknown shifts of tomorrow. It is this forward-thinking, adaptable principle that secures lean product development as an unyielding beacon, guiding businesses through the competitive storm towards delivering excellence and securing customer delight.

As this discourse concludes, entrepreneurs are encouraged to embrace the tenets of lean product development, integrating them into their strategic vision. The outcome? A robust and scalable enterprise poised for triumph, weaving innovation and customer-centricity into the fabric of its corporate narrative. It is this ethos that will catalyze industry leadership and enduring success.

Our dedicated team of specialists can help you implement lean product development to drive efficiency and innovation.

FAQ

What is lean product development?

Lean product development (LPD) is a methodology inspired by lean manufacturing principles, focused on creating products efficiently by eliminating waste, optimizing processes, and continuously improving. It stresses customer value, minimizes unnecessary work, and promotes iterative development.

How do lean principles apply to product development?

Lean principles apply to product development by emphasizing the creation of value for the end user while systematically identifying and eliminating waste throughout the development cycle. They enforce an approach that promotes continuous improvement, rapid learning, and adaptability in the product development process.

What are some core benefits of implementing lean product development?

Implementing lean product development can lead to multiple benefits, including minimizing waste to maximize value, enhancing flexibility and responsiveness to customer needs, achieving faster time to market, increasing team productivity and morale, driving continuous learning and improvement, improving customer satisfaction, and reducing costs while improving ROI.

Can start-ups benefit from lean product development?

Absolutely. Start-ups can utilize lean product development to ensure they are building products that customers truly want while minimizing resource expenditure. It helps start-ups adapt quickly to market changes, focus on innovation, and grow efficiently.

How can established companies integrate lean into their product development processes?

Established companies can integrate lean into their product development processes by aligning their practices with lean principles such as value identification, value stream mapping, fostering a continuous flow, establishing pull systems, and pursuing perfection. They often need to adapt their existing structures to support a more flexible and waste-minimizing approach.

What tools and technologies support lean product development?

Several tools and technologies support lean product development, including Kanban boards for visual management, Value Stream Mapping to analyze and design flows to eliminate waste, and analytics tools for gaining insights into customer behavior and process efficiency. Other software tools may support agile methodologies that complement lean principles.

What common pitfalls should be avoided when implementing lean product development?

Common pitfalls include not fully understanding customer value, poor execution of value stream mapping, resistance to change within the organization, and failing to balance lean rigor with the flexibility needed for innovation. Overcoming these requires a strong commitment to lean education, effective communication, and leadership support.

How is lean product development expected to evolve in the future?

Lean product development is expected to integrate more advanced technologies, such as data analytics, AI, and machine learning, to further streamline processes and enhance decision-making. The methodology will likely continue to evolve to address the growing complexity of products and markets while remaining committed to efficiency and customer value.

Is lean product development suitable for all types of products?

While lean product development originated in manufacturing, its principles are versatile and have been successfully applied to a wide range of industries and products, including software, services, and physical goods. Nevertheless, its successful application requires thoughtful adaptation to the context of each unique product and market.

How does lean product development align with agile methodologies?

Lean product development aligns well with agile methodologies as both prioritize customer value, embrace change, and promote iterative cycles of development and learning. However, they have distinct roots and applications, and successful integration can result in a hybrid approach that leverages the strengths of both methodologies.